oil pressure gauge

- Thread starter Greg_M

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

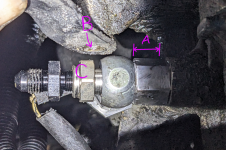

Test fit on my parts engine. I think it'll work. The allen head machine screw holding the colant pipe bracket is the next battle. Several options. Make a new reducing bushing with less of the bolt head retained thereby reducing A. Swap the machine screw with a phillips pan head or similar with a lower profile (B). Reduce the banjo bolt hex dimensions C. Or a combination of all three. Alternatively I could find some other way to secure the coolant pipe.following this

that's about where I got stuck

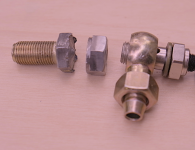

Today i finally got around to installing my oil pressure gauge on my 95 D1. My D1 is a distributor car but i run a serp belt motor with an interim front cover that has a hole for a distributor. So i have a crank driven oil pump and a Distributor and my oil cooler lines are blocked off. I was always curious what my oil pressure was with the oil lines blocked off and since i wheel my D1 pretty hard and it spends a lot of time at weird angles. After spending countless hours trying to find adapters i finally decided on breaking open a factory style sensor and trying to adapt it to work since it had the best sealing surface out of anything i could find/make. After breaking the sensor apart it became clear that i could probably just tap it to 1/8 NPT and thread in my adapter. Then with some creative adapters i was able to install a factory sensor as well, so no idiot light. All in all, i think i spent about $30 in parts. Ignoring the thousands i have in tools lol. I took some pictures through the whole process so if anyone wants to see i can post them.

Attachments

Here is a video, #1 of 2, that show how to install an oil pressure gauge on a Discovery 4.0L.

That's a really good way to do it. I install oil fed intermediate shaft covers on 911s and you get your oil pressure from a similar set up, an oil filter adapter with a port on it.Here is a video, #1 of 2, that show how to install an oil pressure gauge on a Discovery 4.0L.

This is bar far the easiest method, I've just had bad experiences with glow shift oil filter adapters leaking and a lot of my friends have had similar issues so I wanted to try a different way.Here is a video, #1 of 2, that show how to install an oil pressure gauge on a Discovery 4.0L.